When it comes to choosing plastics bags, two options are often considered: polyethylene (PE) or polypropylene (PP) plastic. Although polyethylene and polypropylene bags are both plastics, they aren't typically used for the same purpose or products. Deciding which type of plastic packaging to use depends on your specific needs and application.

Understanding PE and PP Bags: What's the Difference?

What is a Polyethylene bag?

Polyethylene bags are translucent or opaque with a slight haze to them that allows you to see the items inside, although the details of the contents won't be clear. Polyethylene bags are ideal for packaging goods or items that require a high level of protection. Most industrial companies use polyethylene bags for packing and storing large, heavy items such as industrial machining parts.

The main characteristics of polyethylene bags include:

- Translucent or opaque

- Tear resistant

- Flexible

- Durable

- Low abrasion

- Soft and pliable

What is a Polypropylene bag?

Polypropylene bags are crystal clear, making them ideal for food, the medical industry, or any other industry where consumers need to clearly see a product before making a purchase.

The main characteristics of polypropylene bags include:

- Durability

- Corrosion resistant

- Crystal clear transparency

- Pliable at higher temperatures

- Stiff and hard plastic

- High environmental resistance

Before deciding which is the best plastic bag to use, consider your specific business needs, your budget, and how you want to package and present your products to your customers.

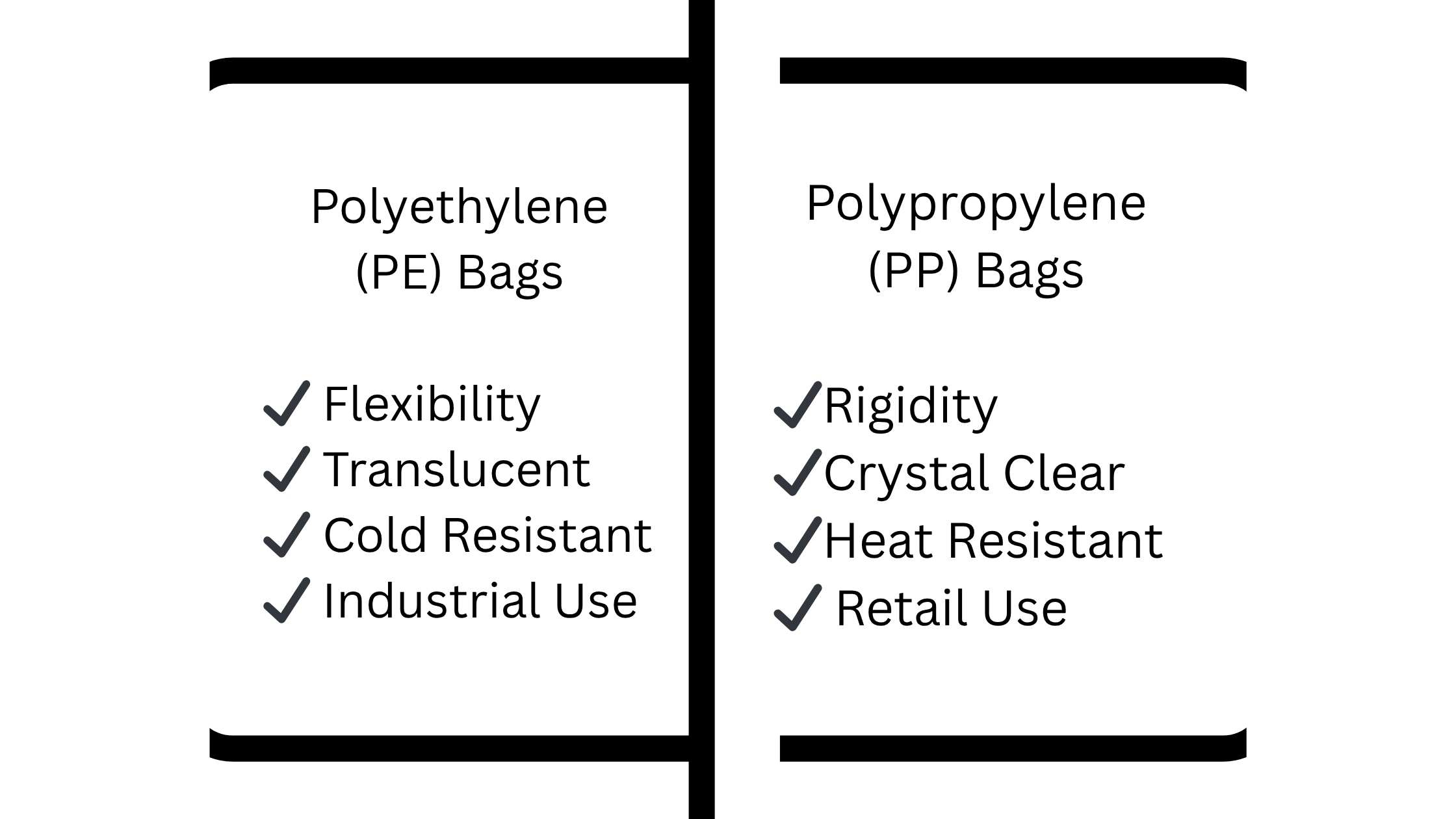

Comparison of PE (Polyethylene Bags ) vs PP (Polypropylene Bags) -

| Feature | Polyethylene (PE) Bags | Polypropylene (PP) Bags |

|---|---|---|

| Appearance | Translucent or opaque | Crystal clear |

| Flexibility | Soft and pliable | Stiff and rigid |

| Temperature Resistance | Excellent in cold environments | Performs better at high temperatures |

| Chemical Resistance | Moderate | High |

| Cost | Lower | Slightly higher |

| Best For | Industrial and heavy-duty packaging | Retail, food, and medical packaging |

| Recyclability | Yes (varies by type and facility) | Yes (recyclable in many municipalities) |

PE (Polyethylene) Bags Advantages

Polyethylene has several advantages, including exceptionally high melting and freezing points. It is created by the polymerization of ethylene (or ethene) monomers. Polyethylene is made by the addition or the radical polymerization of ethylene (olefin) monomers.

Some of the properties and benefits of polyethylene bags include:

- Inert and translucent, which creates a lower static charge

- Preventing too much light from entering the bag, which protects the contents

- Attracting less dust, dirt, and other undesirable foreign organic elements

- Less costly than polypropylene

- More resistant to cold temperatures and wear and tear

- High-density polyethylene (HDPE): Features densely packed and bonded molecules, making this type of polyethylene rigid, robust, and durable.

- Low-density polyethylene (LDPE): LDPE is generated from free radical polymerization, resulting in long and short branching of chains. This type of polyethylene is flexible, with low tensile strength and durability.

- Linear low-density polyethylene (LLDPE): LLDPE is very strong and durable. It boasts a higher tensile strength and durability than the LDPE.

Polypropylene - PP Bags Advantages

Characterized by a more transparent appearance and higher tensile strength, polypropylene bags offer a higher heat and chemical resistance than polyethylene bags. Polypropylene packaging can be made with rigid protective edges, making it ideal for wrapping solutions that prevent scratches to the product or contents. It also offers unmatched protection against moisture, vapors, and debris. Some of the specific properties and benefits of polypropylene bags include:

- More resistance to chemicals, high temperatures, and scratches

- Stiff and hard plastic

- Crystal clear for excellent product presentation

- Unmatched vapor and moisture barrier

- Meeting FDA and USDA specifications and requirements

Applications of Polyethylene Bags and Polypropylene Bags

Polyethylene Bags Applications -

Polyethylene bags are used in a variety of domestic and industrial applications, including making pipes, bottles, cans, tubing, plastic film wraps, polythene grocery bags, and much more.

Polypropylene Bags Applications -

Polypropylene bags are commonly used for food wrapping, electronics manufacturing, and hospitals to keep contents free of contaminants. They are also used for packaging a vast number of consumer products in a wide range of industries and applications, including the automotive industry.

What is the difference between polyethylene and polypropylene bags?

PE bags are more flexible and cost-effective, ideal for industrial and heavy-duty storage, while PP bags offer superior clarity and strength, making them suitable for food, medical, and high-end product packaging. Choosing between them depends on your specific packaging needs.

PE bags are more flexible and cost-effective, ideal for industrial and heavy-duty storage, while PP bags offer superior clarity and strength, making them suitable for food, medical, and high-end product packaging. Choosing between them depends on your specific packaging needs.

Packaging Solutions by Universal Plastic

Polyethylene and polypropylene poly bags are undeniably the two most commonly utilized packaging solutions. When deciding the best option for your needs, it is crucial to know the advantages that each offer. If you need help choosing the right one, reach out to Universal Plastic today. Our experts will work closely with you to understand your application requirements. Later, we can customize these bags with your brand logo and text for branding and promotional purposes and offer them in the best wholesale prices. Contact us today to discuss your requirements and request a quote.

Frequently Asked Questions (FAQs)

1. What is the main difference between polyethylene and polypropylene bags?

Polyethylene (PE) bags are more flexible, durable, and cost-effective, whereas polypropylene (PP) bags are stiffer, crystal clear, and more resistant to heat and chemicals.

2. Which type of bag is better for food packaging?

Polypropylene bags are ideal for food packaging due to their clarity, moisture resistance, and compliance with FDA and USDA standards.

3. Are polyethylene and polypropylene bags recyclable?

Yes, both PE and PP bags are recyclable, but availability depends on local recycling programs and bag type (HDPE, LDPE, etc.).

4. Can I use polyethylene bags for storing sharp or heavy items?

Yes, especially high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) bags, which are highly durable and tear-resistant.

5. Do polypropylene bags offer better product visibility?

Absolutely. PP bags are crystal clear, making them perfect for retail or food products where visibility is important.

6. Which bag material is more affordable for bulk purchases?

Polyethylene bags are generally more cost-effective, especially for industrial or heavy-duty use.

7. Can these bags be customized with my brand logo?

Yes. Both PE and PP bags can be custom printed with your logo, brand colors, and messaging.

8. What industries commonly use polyethylene bags?

Industries like manufacturing, logistics, agriculture, and hardware use PE bags for packaging, protection, and transport of parts or goods.

9. Are polypropylene bags heat-resistant?

Yes, PP bags can withstand higher temperatures and are suitable for sterilization or heat-sealed packaging.

10. How can I choose the right bag type for my business?

Consider your product type, packaging environment, budget, and visibility needs. You can also contact Universal Plastic’s team for expert guidance and custom recommendations.